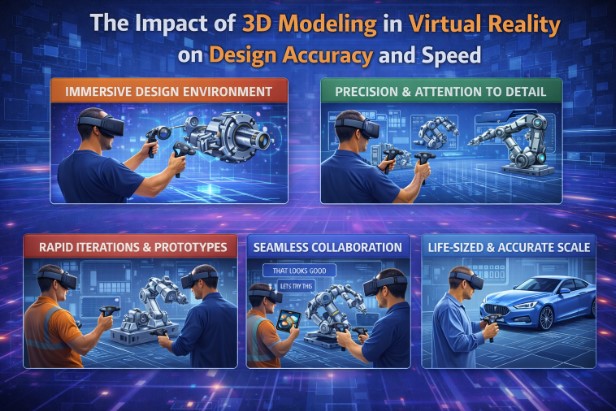

Two of the biggest challenges when creating digital assets for quite some time now have been design accuracy and development speed. Complexification of products, environments, and experiences strains the capabilities of traditional screen-based workflows.

Designers must constantly interpret depth, scale, and spatial relationships through flat displays, which can lead to slower decision-making and errors materializing late in production. This is where 3D modeling in virtual reality is fundamentally changing how teams approach accuracy and speed in design.

Why Accuracy and Speed Are Closely Linked

Late detection of design errors necessitates reworks, revisions, and, at times, full redesigns. These backward steps help in achieving accuracy but greatly compromise speed. The earlier the detection of a design problem, the quicker and cheaper it is to rectify.

More often than not, the most effective ways to speed up overall production timelines will involve improvements in early-stage accuracy.

Eliminate Spatial Guesswork

Virtual reality eliminates this guesswork by placing designers inside the space they will create. Assets can be viewed at true scale, walked around, and evaluated from natural perspectives. Proportions that might seem acceptable on-screen immediately reveal themselves as incorrect in immersive space.

This instantaneous spatial feedback greatly increases accuracy from the very start of a design.

Faster Decision-Making by Means of Real-Time Feedback

Every step introduces latencies, particularly as feedback can come from several sources.

In immersive environments, feedback is instantaneous. A designer can make changes to form, spacing, and layout in real time and see the outcome immediately. Fewer revision cycles are needed to reach approval.

Speed improves not from corners cut, but because of a reduction in uncertainty; decisions are made more confidently with fewer second guesses.

Improved Proportion and Scale Validation

Scaling-related problems are some of the most common in digital design. Objects can be correct in isolation yet feel wrong when placed into a larger context.

Working at a real or exaggerated scale allows designers to validate:

- Proportions of objects to the human body

- Spacing between elements

- Visual balance in environments

3D modeling in VR reduces scale-related rework in production workflows significantly by allowing designers to experience assets the way users will experience them.

Accelerating Early-Stage Ideation

The earliest stages of the design process are where speed is most critical: teams must explore ideas quickly, discard weak concepts, and refine promising ones without excessive investment.

It is in this area that VR-based modeling truly shines: allowing designers to block out ideas extremely quickly, make large adjustments in a rather intuitive manner, and freely experiment without a priori concern for technical precision.

Since forms are generated directly in space, ideas come much faster and are less hindered. This accelerates creative exploration while preserving design intent.

Reduce Interpretation Errors among Teams

Design accuracy is not just about the designer; rather, it is also about how well others understand the ideas. Misinterpretation between designers, engineers, and stakeholders or clients usually causes revisions and delays.

Immersive models provide that common spatial reference that everyone intuitively understands. Instead of explaining dimensions or pointing at screenshots, teams experience the designs together.

This shared understanding:

- Reduces miscommunication

- Speeds up approvals

- Minimizes redesign because of misunderstandings

Accuracy improves since everyone is aligned on what is being built.

Simplify Review and Approval Cycles

Reviews can be a design pipeline bottleneck. Stakeholders may find it difficult to visualize designs through traditional drawings or renders; this can result in hesitation or repeated rounds of feedback.

Direct experience of designs in VR leads to more specific feedback. Questions are solved immediately, and often it’s possible to try out the changes on the spot.

This only reduces approval cycles and smooths out the progress of projects.

Maintaining Creative Flow while Increasing Precision

One of the subtler costs of traditional modeling is creative disruption. The constant switching of tools, camera adjustments, and technical checks interrupts creative flow.

It reduces these interruptions by keeping the designers focused on form and spatial relationships. Precision improves not because designers are slowing down, but because they can remain engaged and present throughout the process.

This sustained focus leads to cleaner forms, stronger composition, and fewer downstream corrections.

Hybrid Workflows Preserve Technical Rigor

It is important to underline that VR modeling does not substitute the classical production pipelines but extends particular stages when speed and spatial precision are more crucial.

Most teams use VR to:

- Concept Development

- Scale validation

- Layout and spatial planning

Assets then go into traditional tools for detailed refinement, topology optimization, and final production. This hybrid approach ensures that speed gains and gains in accuracy do not compromise technical standards.

This is where experienced 3D modeling services make a difference: they guarantee that immersive creation translates into production-ready assets without losing any quality.

Long-Term Impact on Project Timelines

The real value of VR modeling is not in specific design sessions but on full project timelines: fewer revisions, faster approvals, and reduced rework compound over time.

Projects benefit from:

- Shorter development cycles

- lower production risk

- More predictable delivery schedules

Speed improves as accuracy is built in from the start rather than corrected later.

Competitive Advantage Through Better Design Decisions

The ability to make fast, accurate decisions in design enables strategic advantages in competitive industries. Teams adopting immersive workflows get a clearer view of their designs earlier than competitors who are dependent on traditional tools alone.

This advantage translates to:

- Faster Time-to-Market

- Higher design quality

- Stronger stakeholder confidence

Conclusion

Design speed and accuracy are not opposing forces but complements when the right tools are used. By eliminating spatial guesswork, accelerating feedback, and enhancing early validation, 3D modeling in virtual reality is redefining how designers approach both precision and efficiency.